Application Overview

Aras Simulation Management is a powerful solution that enhances collaboration and decision-making between simulation and other engineering domain experts at every stage of the product lifecycle. Its tool-agnostic data model allows linking SPDM (Simulation Process and Data Management) silos with the overall product's Digital Thread managed by the Aras PLM platform. The resulting traceability provides simulation activities and results with a specific product context at every level of product representation and every step of the product's lifecycle. Traceability includes all digital assets represented in Digital Thread, such as requirements, functions, architecture, variants, implementation domains, and others. This allows for an integrated, traceable, and verifiable approach to simulation, leading to better product performance, reduced risks, and improved decision-making.

Ansys Minerva SPDM, powered by Aras

Ansys Minerva SPDM, powered by Aras, is a best-in-class SPDM solution that provides a system of record for exploring, defining, and executing simulation studies. However, it does not manage product data such as requirements, structures, variants, engineering and manufacturing Bill of Materials (BOMs), documentation, and other digital assets managed by PLM platforms. By linking Ansys Minerva with Aras Simulation Management, users can relate SPDM-managed simulation studies with the overall product Digital Thread managed by the Aras PLM platform, providing a traceable and configuration-managed product context to the users of SPDM and PLM.

With our open ecosystem approach, this unique collaboration combines the strengths of Ansys’ industry-leading multiphysics portfolio and the resilient platform from Aras for digital connectivity to dramatically enhance customer value.

We see the Ansys partnership as game-changer for simulation and engineering processes that provide traceability, connectivity, and reuse across the product lifecycle. Aras supports Ansys’ open ecosystem approach to simulation management to help accelerate our joint customers’ digital transformation processes.

Digital Thread and Simulation Tasks

To further enhance traceability and efficiency, Aras PLM platform offers Task Automation component, allowing Simulation Management to trigger tasks according to an execution template. This enables Simulation Management to trigger simulation-related tasks on its own or to request the execution of such tasks via SPDM (Simulation Data & Process Management) solutions. Execution templates support the definition of the execution logic, business logic, and execution environment. The component is not specific to simulation activities and can automate any interactive or batch environment locally or remotely.

Toyota Motor Europe Use Case

Find out how TMC (Toyota Motor Europe) uses Digital Thread managed by the Aras PLM platform to organize basic engineering data in the context of simulation. By leveraging PLM services such as revision control, configuration management, and low-code methods, TMC can automatically generate families of engineering models (geometric and non-geometric) with multiple versions and variants traceable via Digital Thread. This tool-agnostic and enterprise-wide configuration enables cross-domain collaboration using the same definition and understanding of the engineering problem. In the future, these will serve as input to SPDM processes. According to TMC, this approach allows to capture fundamental design issues from the perspective of a problem instead of a solution.

Find Out More

Related Topics

Aras Enterprise SaaS

Aras Enterprise SaaS provides a fully capable, business ready PLM environment with Systems Engineering and Digital Thread functionality to transform your organization.

Explore Your Options

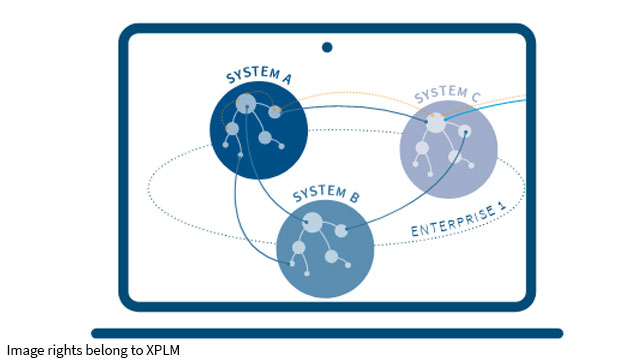

Systems Thinking

Manage complexity by applying Systems Thinking to your Digital Transformation. Benefit by mitigating emergent properties and optimizing system-of-systems environments.

Systems Thinking

Systems Architecture

Create tool-agnostic system architecture models from structures authored in external system tools and make them part of Digital Thread that links to requirements, simulation and detailed design data.

Systems Architecture

Digital Twin

Build and manage configurations for every product or system of products in the field. Make engineering, operations, and maintenance decisions with monetary impact.

Explore

Connect Everything

Capture your complete, evolving product definition and allow teams across the enterprise to follow a product’s digital history and all of its related digital assets.

Explore

Variant Management

Efficiently manage product variants and maximize reuse of a product platform.

Learn More

Document Management

Manage critical information created throughout the engineering, manufacturing, and maintenance of products.

Explore

Requirements Engineering

Adopt a transformational technology to manage requirements in context with total product configuration.

Learn More

Visual Collaboration

Capturing the conversation demystifies how decisions are made. Visual Collaboration enables users to mark up and comment on items inside the system.

Learn More

Dynamic Product Navigation

PLM data can do more when your CAD viewables become the visual context for your product’s information. Search, navigate, and interrogate PLM data quickly and easily.

Watch the Demo

Change Management

Change is the only constant in manufacturing. See how Aras helps you manage it.

Learn More

Aerospace & Defense

Better manage product-related information and processes specific to mission critical requirements.