Is your digital transformation strategy turning changing business conditions into competitive advantages?

In January, we held a webinar to review “Transformative Business Opportunities During Recessionary Times.” This was an opportunity to set the stage for 2023 expectations and create a framework for organizations potentially heading into recessionary times layering into this elevated energy costs and supply chain disruptions.

While the impact of these trends varies by industry or even by company, let's take a look at the areas we targeted for 2023 and how they may continue to affect our foreseeable future.

Are you responding to trends by Digitally Transforming?

The best way to digitally transform is through iterative projects to support growth; we call this Iterative Digital Transformation - an agile digital transformation strategy which involves investing in smaller, proactive projects to improve the organization continually. The old “big bang” transformation approach does not align with the current economic climate, so it’s time to change. Innovation is still critical to remain competitive and investing in the right projects gives you the competitive edge to become a leader in your space or maintain your leadership position by growing in turbulent times.

Emerging Trend Alert: Artificial Intelligence (AI) for PLM, specifically using AI for Generative Design. This is a great example of the next hot thing that organizations may feel inclined to focus on right now because everyone is talking about it! But don’t spend too many cycles on AI just yet; it’s a bit of hype until we consider the best approach to create value for Generative AI in PLM for organizations.

Solution: Define expectations of Generative AI and align to PLM, to iteratively explore its use and value over time. This is how Aras is discussing the relationship of Generative AI to PLM with our customers:

- The what (as in design data). In the past, PLM was a system of record for mechanical BOM – it provided the answer to what – a system of record in configuration management.

- The why (as in design intent). Today, PLM is including all product representations on the left side of the engineering V model in the digital thread – and therefore, it’s beginning to provide the answer to why for the what. Why is the BOM the way it is? It may include some AI for intelligent search and pattern recognition to interpret the data, but that’s about it.

- The how (as in tell me what to do). Tomorrow Generative AI will allow PLM to become generative all by itself; telling the engineers how in the context of system/requirements/performance targets. In other words, it will first start guiding engineers on what incremental decisions to make (a set of incremental choices), and eventually, it will tell engineers the best solution. It will be able to do that because AI would learn from the past what and why retained in PLM and traceable via digital thread.

Keep in mind, however your approach, it should be iterative. A great example of Iterative Digital Transformation can be found in our recent case study showing how Tamturbo evolved their product offerings into an Air as a Service model, creating a stronger connection and more visibility into their customers’ needs.

Building business resilience is the only path forward:

How well-equipped is your organization’s ability to respond to business disruption? Can you adapt to changing compliance and evolving business conditions? The reality is that we now all work with a distributed workforce, and keeping up with security standards and business expectations is difficult. The goal of business resilience is ensuring your business systems are compliant AND connected, which is internally focused. But you also have to look at addressing and conforming quickly to outside pressures, for example, sustainability policies and government regulations. This includes emerging technologies that you may not even know you need yet but should be prepared to leverage when the time comes.

Emerging Business Disruption Alert: Sustainability. This can range from organizational goals of becoming carbon neutral to designing your products to reduce their environmental footprint. Emerging regulations and compliance activities will continue to evolve, and organizations will need flexibility in their systems and processes to adapt quickly; otherwise, the cost implications, and competitiveness of their solutions could be dramatic. To learn more about leveraging PLM in sustainable product design, read this blog from Patrick Willemsen.

Solution: Avoid adding more tools to address gaps. It creates a high-risk, temporary solution while increasing technical debt. The correct answer is looking for evergreen solutions that mold to your current needs and change – at low cost – to emerging business requirements.

A great customer example is Ottobock, who use PLM to quickly adapt to evolving needs.

Mitigating supply disruptions will continue

Supply chain! There is no indication supply chain issues are going away anytime soon. The past two years have shown us that we rested on our laurels when it came to our supply chain, thinking of it as a one-way street where we press our suppliers for cost-effective parts, fast, on-time delivery, and blame them when it doesn’t happen. Keep the supply chain top of mind and look for creative ways to address the many aspects of supply chain mitigation.

Emerging Supply Chain Trend Alert: There are simmering tensions on the west coast, a work slowdown that could evolve into a full strike. Are you ready for it? Have you considered the effect on your business when 22,000 longshoreman strike at ports bringing 42% of our imported goods?

There are myriad opportunities to move static supply chains to dynamic ones while creating a competitive advantage for the product. It starts with increasing visibility by connecting your suppliers and customers to your supply chain processes – across the entire product lifecycle.

Solution: Bolster your supply chain through a systems engineering approach to identify multiple ways to implement the functions of a product. Get the proper visibility to alternate sources of components EARLY in the engineering cycle – all too often, we are reactionary here, costing time and delays in product manufacturing and delivery.

But don’t take my word for it; a great example of harnessing the power of connectivity is told by our customer Microsoft.

Continue to evaluate your position against your peers

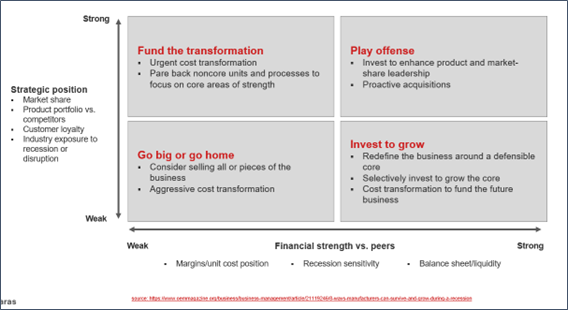

It’s important to keep taking stock of what is possible based on comparing your position vs. your peers. Here is a good framework to consider when evaluating yourself and others and what actions to take during difficult times.

Many manufacturers use this framework to determine the focus of resources, what their organization is good at, and more importantly, how to invest in becoming more competitive and set up the organization to emerge as a leader as economic times improve.

It’s important to be mindful that no matter the disruption or changing business requirements, it can be treated as an opportunity for discrete manufacturers to invest in the right things, leading to future success.

Do you want to see what else Aras has to say on current market trends? Watch the on-demand version of our “Hot Takes” webinar, where Aras gives our spin on the latest topics in the news and what they mean for PLM.