As artificial intelligence (AI) is making headlines worldwide, it seems that the negative press has overshadowed the potential of AI to make positive impacts across many disciplines. This is nothing new. With any emerging technology, there are bound to be visionaries who foresee the potential to drive society forward and concerned groups who fear the misuse of new technology will create more chaos than good.

While the adverse effects of AI seem to be getting the most attention, and there is certainly cause for concern, I don’t believe many of these people understand the upside of AI. I believe the misunderstanding lies in the complexity of AI and the intricacies of applying AI to the highly developed processes it will significantly improve. In industry, many companies have not taken the appropriate time to understand the relevant use cases. Instead, they have committed to AI as a technology and then started searching for a problem to solve.

A PLM Use Case

Let’s look at a realistic PLM use case and compare how it could be handled before introducing AI and how AI might facilitate the same scenario. I realize I am oversimplifying the process for the purpose of the blog, but I think this is a good example to make the point.

Let’s assume we are a company designing, manufacturing, installing, and managing wind turbines worldwide with an installed base of roughly 10,000 units. A very astute engineer reviewing IOT data has noticed the efficiency of several turbines has unexpectedly decreased over the past few months. These units are located in different locations and, on the surface, do not have any noticeable differences from other installed units.

Previously, an engineer might start identifying the issue, determine why only specific units are affected and what they have in common, and create a corrective action plan for the field. Even if his company has a somewhat developed Digital Thread where much of the company’s product data is effectively connected, the process will take some time as he researches and analyzes potential root causes and other related issues.

In a company where AI is employed, the engineer would direct the technology to research several possible scenarios. AI could quickly run through the company’s Digital Thread and additional outside data points to determine what may be causing the loss of efficiency and draw conclusions regarding what is unique among these wind turbines. It could look at data from outside the company’s internal digital thread, like unusual weather patterns that could impact the turbines' operations or perhaps quality issues from part data maintained by third-party suppliers. This information could be combined with internal activities like design changes and maintenance activities on the wind turbines.

In my use case, I imagine the affected wind turbines had the same upgrade performed with their recent maintenance activities. The upgrade contained a newly designed component replacing parts of the original design. Under the engineer’s direction, AI could connect the upgraded component with unusually hot weather in the regions where the affected wind turbines reside, potentially causing a degradation in performance.

Based on previously established models, AI might also look back at the requirements of the original component pulled from the Digital Thread to see the original design intent and determine possible root causes. (See The Future of Product Innovation and PLM – Abstraction, Digital Threads, and Artificial Intelligence by Paweł Z. Chądzyński for an excellent article on this topic.) Perhaps the requirements in the original design would indicate temperature tolerances for parts to reduce the risk of losing the unit's efficiency if temperatures reached a certain level. Looking at the upgraded component from the as-maintained BOM in the Digital Thread, AI can verify the parts used did not meet these requirements and prescribe recommended changes to Engineering. I think we have something here.

I am also imagining that the value of having AI wouldn’t stop there. AI might analyze if any other wind turbines in the installed base are at a high risk of developing efficiency issues due to using inappropriate parts and create a recommended plan with options for service teams to address the issue in the field based on location and severity.

AI can also be trained as a virtual assistant to support meeting planning, task organization, and approval workflows, including updating customer-facing, manufacturing, and service documentation.

Of course, the most important part of this whole scenario is verifying the data and assumptions AI is proposing. The work of experienced, knowledgeable engineers and other subject matter experts is vital to authenticate the findings. AI may only introduce partial solutions based on the models it is working from, but it takes human intellect to know how to interpret the information, direct AI’s additional analysis and conclude what is best for the situation. Engineers and their counterparts always need to be the decision makers in the process.

AI, Digital Thread, and the Cloud

To reiterate an earlier point, while the scenario is a realistic example of an issue that could happen in a business, how the business would react and how the plan would be executed is certainly an oversimplification. What is foundational to be able to work in this advanced state are the critical technologies for AI to operate effectively. Let’s talk about the Digital Thread, AI, and something that hasn’t been mentioned yet, the cloud.

Digital Thread and AI

The digital thread is not a new concept, but not all companies have fully embraced the strategy yet, and that will be an issue for them. As AI continues to develop and establish itself in the day-to-day operations of a business, the amount of data it will demand to effectively analyze complex scenarios will grow exponentially. A digital thread gives companies a strong foundation to grow their analytical capabilities and provides AI an effective design to access and relate data. The greater the quantity and quality of data AI has to work from, the better results will be created. (Garbage in/garbage out – some things never change.)

Data-as-a-Service

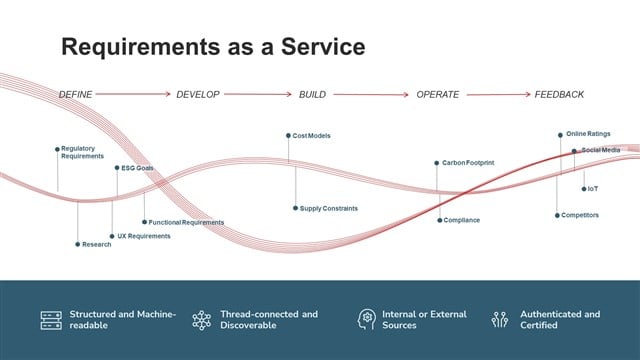

Another interesting option to consider is Data-as-a-Service. A good example to consider in the PLM space is how companies will manage regulatory and compliance requirements. Staying current with the growing number of requirements is time-consuming and expensive. With Data-as-a-Service, a company can subscribe to a third-party supplier of regulatory requirements data delivered in a format that would be easily consumable by a PLM system or requirement management system making it accessible by a company’s digital thread.

The supplier would be responsible for keeping the requirements current and modifying them as necessary as well as providing business use cases for an organization to follow for testing and other activities. The data would provide higher data quality, increased detail and more up-to-date information to a company’s digital thread. This and other examples like this illustrate how a company’s digital thread will grow from outside sources with minimal effort from its own internal resources.

From Rob McAveney’s (Aras CTO) ACE 2024 keynote presentation “On the Thread to What’s Next”

And of course, the Cloud

No technology conversation is complete without understanding the role of the cloud and SaaS. With AI’s need to process vast amounts of data to produce accurate and complete results, IT organizations will need to scale their environments faster and more effectively than ever. Additionally, AI will need data from inside and outside their internal environments, connecting new sources of data to their Digital Thread quicker than ever anticipated. More data, more connectivity, more processing power, more security, more flexibility, more everything. If a company’s data center hasn’t struggled to keep up with the increasing demands of their organization yet, AI will certainly stretch its capabilities to the limit.

The other point to consider is the role of SaaS. As AI is forcing the hyper-growth of the Digital Thread discussed above, there will be an increasing need for the technical specialists of PLM solutions to manage the increasing complexity of the system. These professionals are expensive and often difficult to find. Many companies are looking to their PLM providers to supply the necessary expertise to manage growth through SaaS offerings. For companies already on SaaS, congratulations! You are already one step ahead of your competitors.

In conclusion...

The idea of AI-infused engineering starts with data – new ways of tracking and visualizing thread-connected information will emerge to help us see problems from new angles. None of us should underestimate the impact AI will have on the future of engineering. We should be embracing the idea that repetitive or non-value-add work can be done by a machine.

Sometimes it is hard to conceptualize the future, especially when it involves complex ideas that only the experts in a particular discipline truly understand. While some may be fearful of AI, this may be because they only see the simple use cases that potentially create harm. These concerns are certainly valid and must be governed if AI is to succeed, but understanding how AI can effectively prevent disasters is also a valid conversation that needs to be discussed. Let’s say I change my earlier scenario to the following,

On the morning of Tuesday, say, January 28, 1986, somewhere in Florida, a very astute engineer sits down at his desk and reads an analysis from his AI assistant. After analyzing the data, AI has concluded that due to the record-low temperatures in the area, two small parts, O-ring seals, were at risk of failing on the launch of the space shuttle. AI ran several simulations, and they show that there may be a failure of the primary and secondary redundant O-ring seals in a joint in the shuttle's right solid rocket booster (SRB). Perhaps with this level of solid evidence provided at the right time, the Challenger launch would have been delayed.

Just saying.

Be sure to join Aras at our webinar “From Regulation to Reality: Harnessing AI to Extract Regulatory Requirement into PLM” on Tuesday, April 23, 2024 at 4:00 p.m. CEST. The webinar explores the future of product compliance management, where AI-driven automation and PLM integration converge to redefine product development processes and ensure compliance from regulation to reality. The webinar will be held in English.

Also, take a look at Rodrigo Britto Maria’s latest blog “PLM Tales in Space: Aras Innovator and the Digital Thread” for an interesting look at why Aras Innovator is a PLM solution for the space industry.