Are you exploring ways to use Aras Innovator applications to amplify Digital Thread use cases? Looking to unlock even more productivity gains? Aras Advanced Visualization builds on our existing, powerful 3D visualizations capabilities to visualize and collaborate with large, complex assemblies, while reducing reliance on expense CAD and other analysis tools.

In the rapidly evolving landscape of digital, connected, and automated products, product integrity must be ensured through compliance with various regulations, norms, and standards. In the automotive industry, digitalization, electromobility, and automated driving have pushed regulators to new heights, with a 10-fold increase in regulations in the last 5 years. This continues to reshape the automotive industry, and the need for a robust solution to navigate regulatory compliance becomes essential. Regulations aren't just product requirements; they are complex and critical tasks that must be met with an integrated organizational approach.

In this webinar, we will dive into the complexity of the product compliance landscape and discover how AI enables a new way of managing regulatory requirements and seamless integration with product lifecycle management (PLM) systems. Learn how data can be created from regulatory documents to facilitate a data-driven approach to technical compliance. By automating the extraction of regulatory requirements from technical documents such as regulations, legislation, and standards, AI streamlines the flow of critical information directly into the PLM system, with the data effortlessly integrated into the development process. However, it is not only the initial integration of regulatory requirements that is key to modern product compliance solutions but also the monitoring and continuous updating of these requirements. A data-driven approach increases efficiency and reduces manual processes, resulting in significant cost savings and an added layer of regulatory security.

The traditional rip-and-replace approach to software architecture transition is not sustainable. Technological advances improve the value of computing by unlocking new capabilities and improving the efficiency of solution delivery. Today, the cycle is repeating itself with cloud / SaaS offerings. How do you break the expense rip-and-replace cycle? With a platform that optimizes your data using composable applications, low-code, and integrations to reduce TCO and build long-term ROI.

Welcome to the first in our thought leadership speaker series exploring the digital enterprise's transformation from the perspective of the digital thread. We will be joined by recognized experts in their fields known for their innovative ideas and insights that will cut through the hype, question conventional thinking, and challenge you to think independently.

As the entire industrial sector (along with the world at large) races to digest the implications of digital transformation, enterprise teams – and in particular, engineers – are radically changing how they approach designing, manufacturing, launching, and servicing products. The importance of interconnected data and digital information frameworks (i.e., digital threads) becomes increasingly clear as teams collaborate and make decisions at a pace not imaginable only 10 years ago.

In this inaugural episode of Pulling the Digital Thread, we'll leverage recent global survey research and analyst commentary to guide a conversation about industry-shaping forces, including Generative AI in Digital Engineering, PLM strategies for supporting ESG Goals, SW-Defined Products, Next Generation Compliance, and more.

Sharing engineering data outside of your organization with suppliers and partners can be a complex requirement to support. Product organizations rely on these companies to augment their existing operations. Learn from Leigh Young, Aras Product Manager, how our latest offering, Aras Supplier Management, enables secure, remote access to controlled subsets of your digital thread and related PLM information through configurable apps.

Join PwC Germany and Aras for a transformative webinar experience, "Don’t Waste Your Company’s Money – Unlock the Power of PLM". In this session, we address a critical issue for Boards worldwide - the inadvertent waste of valuable resources and money due to limited awareness of the capabilities of a holistic approach to Product Lifecycle Management (PLM).

Our webinar will explore three essential themes to shed light on the transformative potential of PLM:

- PLM as a Holistic Strategy: Discover the power of PLM as a comprehensive strategy that can reshape your approach to product development and lifecycle management. Learn how integrating PLM can drive efficiency and innovation and provide a competitive advantage.

- The Board's Role in PLM Strategy: We firmly believe that Boards should be actively engaged in their company’s PLM strategy. Learn why optimizing processes holistically and connecting your tool landscape is essential for achieving success.

- Navigating Common Pitfalls: Gain insights into a prevalent pitfall – relegating PLM transformations to lower organizational levels without adequate change management. Learn how to implement a structured and effective organizational change management strategy and commitment to ensure that PLM initiatives yield maximum returns.

This session features perspectives from two industry leaders, Aras and PwC Germany, representing both the tool developer and business integrator angles. Together, they will provide valuable insights on executing digital transformations effectively. Join us as we embark on a journey to maximize the benefits of PLM, drive innovation, and ensure sustainable growth.

Malgré les nombreuses crises, la plupart des entreprises du monde entier sont optimistes quant à l'avenir. Elles voient des opportunités et veulent les saisir avec de nouvelles idées, de nouveaux modèles d'affaires et de nouvelles stratégies. La transformation numérique est le principal levier permettant aux entreprises de conduire l'ensemble de l'organisation vers demain. L'intelligence artificielle (IA) et le développement durable sont les deux mégatendances qui interpellent actuellement toutes les entreprises et sont associées à des projets à forte intensité de données. Pour réussir dans ces initiatives, il faut disposer d'une base de données solide. Cependant, de nombreuses organisations doivent encore en constituer une.

Aras a récemment mené une enquête auprès d'entreprises industrielles du monde entier sur ces questions et de nombreuses autres. 835 dirigeants des États-Unis, d'Europe et du Japon ont partagé leurs points de vue détaillés sur les enjeux et les perspectives.

Vous trouverez des réponses passionnantes dans la nouvelle étude internationale d'Aras, « Regard sur l’avenir 2024 – Quelle industrie demain ?».

For the development of complex systems such as space systems, concurrent engineering processes are being increasingly used to integrate different engineering teams. These processes are supported by and dependent on computer systems that enable reliable data exchange and design review, verification, and validation processes. However, it is a major challenge, in practice, to obtain the right data, at the right time and from the right stakeholder.

ECSS (European Cooperation for Space Standardization) is a collaboration among European space agencies to provide a coherent set of standards for use in all space systems developments and operations in the European community. ECSS recognized the importance of adopting a standardized approach to data sharing and proposed some standards. As there are many different families of space systems, each with different data and IT requirements, it is unfeasible to establish a single, central data repository for a space project.

Therefore, ECSS recommends a data standardization approach at the semantic level, using a global conceptual data model containing all meaningful data from all system disciplines and whose scope encompasses the entire space system lifecycle. This would be the basis of a "Space Systems Data Repository", which is a collection of different databases logically integrated into an interoperable architecture that allows data to be effectively and reliably exchanged among them.

The Aras Innovator platform provides the flexibility to define custom data models and an open architecture to connect multiple software systems and data sources into a unified platform. In this webinar, Rodrigo Britto Maria, Aras presales engineer for EMEA, will demonstrate why Aras Innovator is the perfect fit to implement a data management solution compliant with the ECSS standards for the space industry.

Sustainability is experiencing increased urgency in corporate strategies. Driven by regulation and customer demand, among other drivers, it is rapidly moving from a topic of discussion to a business imperative for manufacturers. It's time to take a systematic, data-driven approach and operationalize sustainability to drive strategic ESG improvements. Learn why, even though there is no single solution for sustainability, the right PLM solution is essential to support sustainability initiatives in your enterprise.

Kawasaki Heavy Industries, Ltd., a leading manufacturer of equipment for the aerospace, energy, industrial equipment, power, vehicle, and marine industries, has adopted Aras Innovator to streamline new product development and optimize system-related costs.

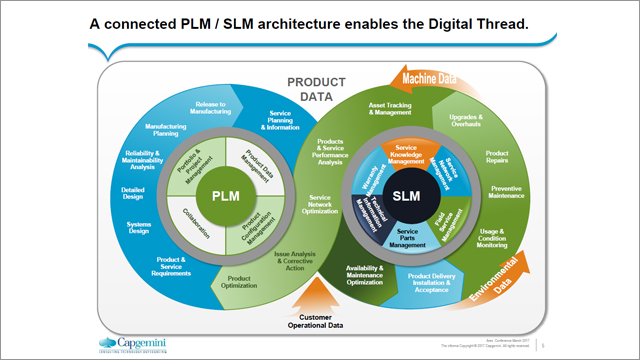

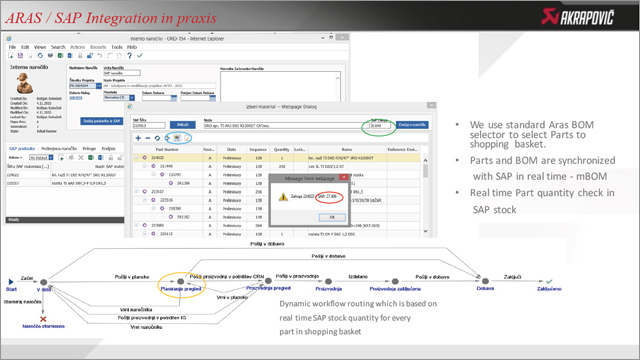

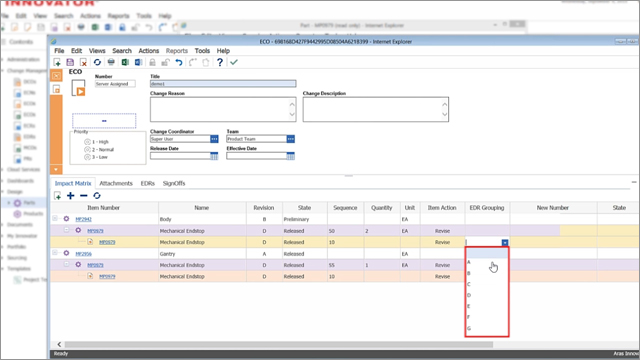

Manufacturing enterprises are often dominated by two major players in IT architecture: Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP). Rather than creating an 'either-or' scenario, the challenge is to create a harmonious interplay between these vital components. Key questions arise, such as:

- Where is the engineering change management actioned?

- Where are the different bills of materials managed?

These are not mere academic queries but critical strategic decisions that shape the efficiency and effectiveness of the enterprise.

In this illuminating webinar, Fraunhofer Institute for Mechatronic Systems Design (IEM), XPLM and Aras will present a live demonstration of the integration between Aras Innovator®, a leading PLM software, and SAP, a top-tier ERP system. This practical demonstration will not only showcase the mechanics of integration but also highlight the profound potential of digital continuity that can be unlocked when these systems work in concert.

Join us as we explore the opportunities and challenges of this integration, providing a comprehensive view of the digitized development process. The goal is to ensure a seamless, holistic management approach that spans all disciplines in your manufacturing enterprise.

In the demonstration Aras shows how maintenance organizations can use the Digital Thread and Digital Twin to support advanced maintenance strategies. With Aras, they have a view into each unique Digital Twin Configuration for assets being managed. They can drill into any asset’s operational status to identify upcoming maintenance requirements before possible unplanned downtime occurs. And they can efficiently predict whether maintenance should occur now or be deferred.

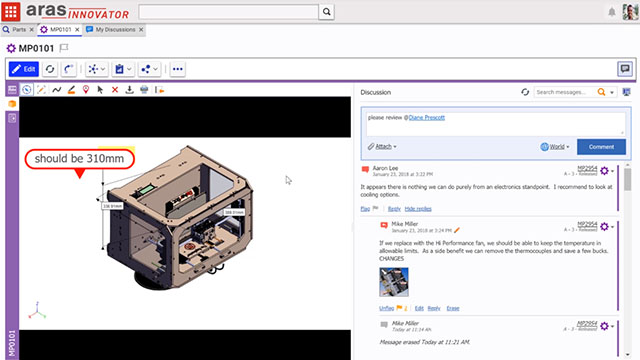

As connected as we appear to be, most companies continue to struggle with effective collaboration. Decision chains are buried in email, functional silos limit access to data, and the data that defines products is scattered across various systems and hard drives. These disconnected decisions and isolated data make it difficult to trace the information that went into creating a single product.

In this session, Aras will demonstrate how organizations can use the Aras platform to collaborate in a unified environment. You will see how a single digital thread of product information connects teams across the product lifecycle. While team members use applications purpose-built for their disciplines, these applications are built on a common platform, the data authored there is inherently connected, and can be easily traversed to enhance communication and collaboration as the product is developed.

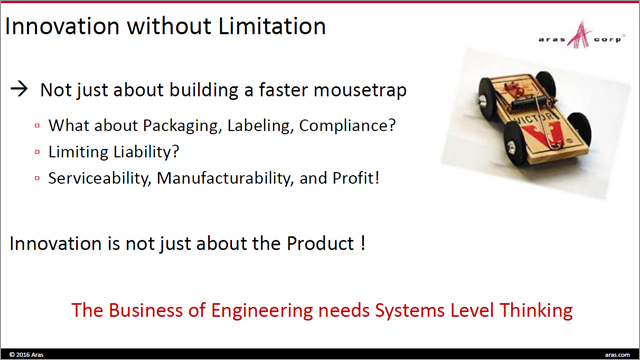

This 30 minute demonstration applies Systems Thinking to making systems models a central part of the digital thread. It demonstrates a practical approach to establishing a custom digital thread that can expand and morph with the complexities of the products and systems that it represents, across all the above initiatives. The digital thread provides access to, and connects, data authored in best-of-class tools, and automatically exposes functionality appropriate to the task at hand—while maintaining traceability and the history of changes across the entire lifecycle.

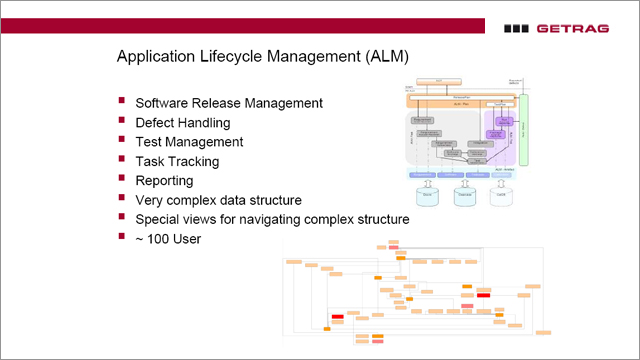

Accelerate your new product introduction with the innovation twins Application Lifecycle Management (ALM) and Product Lifecycle Management (PLM).

Products are getting smarter each year, increasing the ratio among software among hardware components, sub-systems, and the system in its entirety. People from different disciplines need to collaborate to make products and systems work reliably. Furthermore, the pressure to improve the innovation cycle is increasing challenging the market share achieved so far. The different engineering disciplines involved typically work within their specialized tools: software engineering in their ALM system, electrical engineering in data management tools, and mechanical engineers manage data in their PLM system. The know-how exchange between those silos is often poor and results in substantial manual overhead.

In our previous ALM and PLM webinars, we talked about the technology (ALM and PLM: The Innovation Twins) and the business case (ALM and PLM: The Business Case for the Marriage). In this webinar, BHC Consulting, PROSTEP and Aras focus the attention on the methodology and people. Without a good methodology, like Systems Engineering, the collaboration between the disciplines will be cumbersome - despite good ALM and PLM platforms, and sound connecting technology.

EIZO Corporation leverages Aras Innovator to successfully create a digital thread between development and manufacturing. The company, which develops, produces, and sells high-quality video equipment, conducts all of its operations under its own integrated system. Previously, we used PDM (Product Data Management), but in response to the diversification of products, the rapid increase in information, and the promotion of DX in the world, we considered moving to a new PLM system, and decided to use Aras.

CIMdata commentary on addressing sustainability and the Aras platform's ability to do it.

According to IDC surveys, leading organizations believe that Generative AI will have the greatest impact on manufacturing and product design and development in the next 18 months. Despite this, only 27% of companies actively leverage AI in their operations. The challenge is finding practical applications of Generative AI and Large Language Models (LLMs) and gaining organizational buy-in on their use.

Join experts from Aras, the Fraunhofer Institute, and AI Marketplace to explore applied AI use cases for product lifecycle management (PLM).

This panel discussion will cover the basics of AI, Generative AI, and Large Language Models and their application in PLM. We will focus on practical applications, including intelligent documentation, AI-augmented collaboration, and knowledge management. We will present a live demonstration that showcases the practical, tangible implementation of AI in a PLM system, providing experiential insight into the future of intelligent and interconnected product lifecycle management.

In this presentation, Guillaume Fong, Mechanical Engineer & PLM Product Owner of Technip Energies Loading Systems, shares his experiences on replacing an obsolete PDM system and bringing the management of As-Design and As-Built configurations, documents & geometries, engineering changes into Innovator, and how the system provides interfaces with Supply Chain & Manufacturing (ERP), Master Data Management, as well as several custom features.

If you are from a product company or an EPC engaged in project intensive industries, and interested in how other companies manage their project specific design information (tag information) versus the generic product specific information, EBOM (Engineering Bill Of Material). Are you looking into ways of moving from Engineer To Order (ETO) product deliveries towards more Configure To Order, then this webinar is for you.

Bjorn Fidjeland from plmPartner will offer examples of how several companies have implemented solutions for managing both plant engineering and product engineering information in the same platform while utilizing master-data and product libraries to re-use product design data across capital projects.

ESG – Becoming data-centric to enable wise decisions for becoming a more environmentally friendly company and delivering sustainable products has been shown by us through different webinars and white papers. But digitalization must also incorporate the involved people besides transforming paper to data, creating a thread between data elements, and using visualization techniques. Notably, social aspects play a pivotal role within your supply chain, among your customers, and within your workforce.

In this webinar, we explored the “S” in ESG (Environmental, Social and Governance) with Patrick O’Sullivan, Partner at the French consultancy, Findle. The company, founded in 2016 has great expertise in supply chain management, organizational dynamics, and change management. Considering the growing significance of social aspects for companies, customers and employees, we will explore how to integrate people effectively into Product Lifecycle Management (PLM). As we embrace new materials, alternative product design, and improved manufacturing processes to reduce carbon footprints, it becomes imperative that PLM prioritize the human element. Discover practical strategies and approaches for tackling this pivotal subject and learn how to harmonize social responsibility with your sustainability initiatives.

Hear from Aras SVP of Product Management, John Sperling, about the latest capabilities and enhancements to Aras Innovator.

Our product development team has been releasing application, connector, and platform updates, and now with our simplified release schedule, we deliver it all in easy-to-digest quarterly releases! This webinar covers updates from Release 27 to Release 29 that will support your digital transformation efforts, as well as enhanced collaboration across the enterprise with the digital thread. Expand your efforts to new areas of your product’s lifecycle and improve how users view and navigate your most important resource – product information!

Listen to John Sperling do a 30-minute overview and demonstration of all the new capabilities available to help continuously progress your digital transformation initiatives.

Successfully managing the escalating complexity of designing and manufacturing modern software enabled products requires better cross-discipline collaboration and traceability across the product value network. Wipro’s NIMBLE framework enables organizations connecting heterogeneous applications. In this webinar Wipro will discuss its experience of implementing a customer specific Enterprise Data Dependency Management (EDDM), enabling an enterprise-wide Digital Thread in Aras Innovator for the Germany head quartered medical and safety devices major Dräger.

In Product Development, Product Managers need to define and maintain a Product Roadmap. This work usually lacks system support and the means to communicate results in a digital format to other company functions, such as engineering and production, to organize the product data as items in “Bill of Materials” (BOMS). These items include costs, suppliers, drawings, certifications of safety compliance, etc., - data that is relevant for the domain that owns the system.

Building a future product family from a modular architecture, using a Modular Information Model, will improve this situation by offering a common denominator across the product information handling systems to align structure and data. This information model can be executed in the software PALMA, that has been specifically developed for this purpose.

In this webinar, join Tobias Johansson and Johan Källgren from Modular Management, and Tomas Källberg from Aras customer Micropower, offering charging and battery solutions, to learn the reasoning for their choice of PALMA and the intended use case.

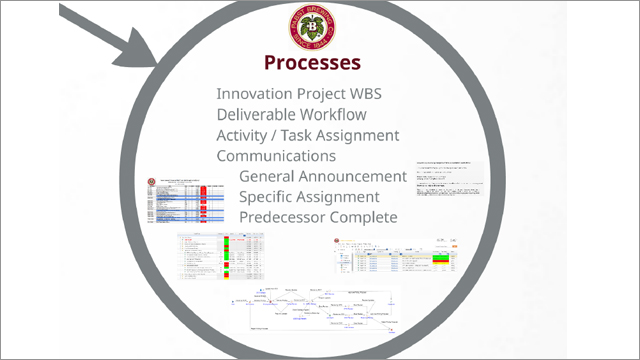

Unlock the full potential of your project management processes. Watch this demo of Dynamic Task Manager (DTM), an innovative add-on module designed to transform project task management for Aras users.

This demo:

- Showcases the seamless integration of DTM with Aras Innovator, empowering organizations to streamline project workflows, enhance decision-making, and foster collaboration.

- Guides you through the powerful capabilities of DTM, highlighting its dynamic and intuitive interface that simplifies project workflows and maximizes productivity.

- Demonstrates how DTM provides in-depth visibility, enabling efficient task management across multiple product development projects.

- Shares inspiring success stories from Kawasaki Heavy Industries and JAMCO Corporation, where DTM has transformed its project management practices.

This demo delves into the implementation process at these customer sites, discussing the challenges encountered, strategies employed, and value attained to ensure a successful transition. See the demo now and take a transformative journey towards enhanced productivity and efficiency with Dynamic Task Manager (DTM).

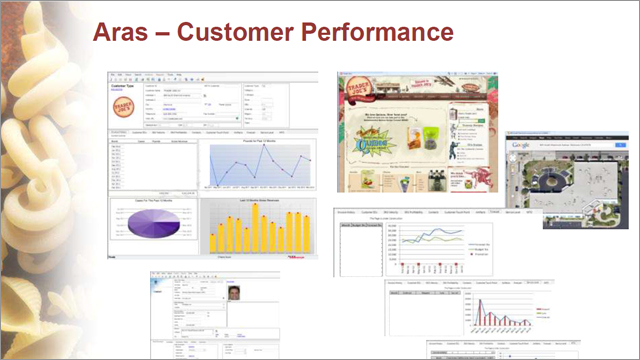

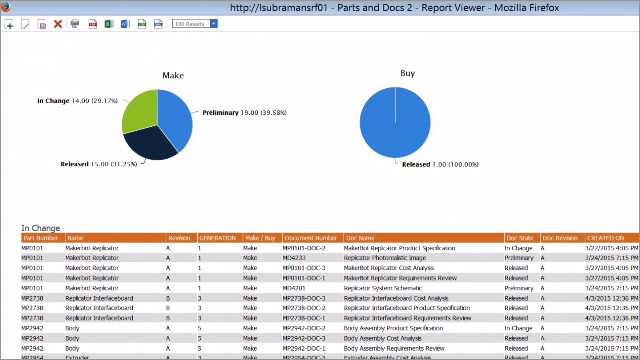

In response to our customers' evolving needs, Aras is excited to announce enhancements to Aras Dashboards and Reporting. Aras users will now have reporting capability and the ability to create custom dashboards to support data sharing and more robust collaboration. Join us to learn how you can better manage your business with greater access across the enterprise to the wealth of data already available in your Aras PLM platform.

Building an enterprise ecosystem for companies engaged in designing, constructing, and operating complex products capable of adapting to changes (be it regulatory, business model, or market shifts) demands a capacity for innovative thinking, connectivity, and collaboration to address your distinct and intricate business hurdles. A comprehensive reevaluation of how product data is managed and shared across the organization, ensuring its security throughout the enterprise, holds paramount importance in the context of digital transformation. Read this eBook to explore obstacles, value, and use cases for creating resilience in your organization.

Aras Innovator is a very feature-rich out-of-the-box PLM solution. It is able to cover the entire end-to-end lifecycle and can be used by any industry. Through the flexibility of the Aras Innovator platform, the system can be configured to fit the specific business process and requirements you have as a company so you don’t have to conform to a software author’s perception of how your business should be run. Instead, you get to keep what makes you unique and gives you the competitive advantage.

For some industries, there are specific use cases and regulatory requirements that are identical for all companies within that industry. To solve this, Aras has made industry solutions that targets the specific and unique requirements of regulated industries to provide a targeted solution that will give our customers best-of-breed solutions to ensure effective engineering and compliance to regulations.

Downstream costs, use of resources and vehicle sustainability are expected to increase 70-80% in the development and process planning phase. It is up to engineering teams to determine the sustainability of an automobile, starting from its operational phase through recycling.

SICK is implementing an interdisciplinary end-to-end PLM concept from development to pro-duction planning. Digitalization and sustainability are linked via the Digital Thread/Twin of the product in production.

Manufacturers who can make themselves less dependent on raw material bottlenecks and skyrocketing raw material prices by using less or switching to recycled materials are set to achieve a significant advantage over the competition.

Recent research from Tech-Clarity reveals that approximately three-quarters of companies prioritize the cloud when selecting software. However, it is essential for companies to prioritize business value when considering cloud-based PLM solutions.

This webinar featuring Jim Brown, president of Tech-Clarity, and Bruce Bookbinder, product marketing manager at Aras who discuss how to align your SaaS PLM strategy with your business objectives and drive maximum value from your cloud solution.

Quadrant Knowledge Solutions’ SPARK Matrix™ includes a detailed analysis of the global market dynamics, major trends, vendor landscape, and competitive positioning. The study provides a competitive analysis and ranking of the leading technology vendors through its SPARK Matrix. Aras was named one of the leaders due to Aras Innovator's:

- Resilient model, consisting of five interconnected layers, allowing seamless modeling of business rules and requirements, using a customizable front end with minimal coding

- A complete view of a product's history and its projected path, enabling businesses to make informed decisions

- Adaptability to guide organizations with flexible and customizable solutions designed to meet their unique business needs

Aras participated in the Software-defined Vehicle track session: “Software-defined Vehicle – Banking on CPU or the Cloud?” at AutoTech: Detroit 2023. In this panel discussion, moderated by Maite Bezerra, Automotive Expert, Wards Automotive, you can view our engaging discussion around the following questions:

- What approaches offer accurate estimates of how much computing overhead to “leave” on major vehicle components to account for future enhancement?

- How do we design hardware and software to be seamlessly updatable over time?

- How much of the core vehicle computer platform should automakers use “off the shelf” from their suppliers instead of designing and sourcing their own?

- Understanding the importance of data management and collaboration in order to keep pace and stay profitable.

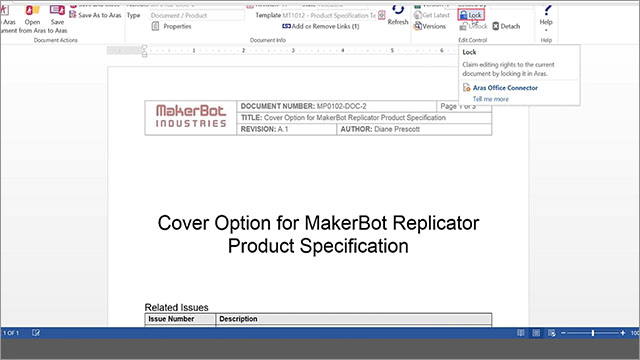

The Microsoft Office Connector for Aras Innovator extends the PLM connector benefits of Aras to users in Microsoft Excel, Word, PowerPoint and Outlook.

Micropower, an autonomous producer of industrial battery chargers and systems, faced hurdles including struggling to locate the most current information and related data, encountering inconsistencies in data, and grappling with reduced search efficiency due to outdated information. The introduction of Aras Innovator brought forth a heightened comprehension of internal processes, resulting in minimized time dedicated to data management, and an overall enhancement in workflow efficiency. Through the adoption of the Aras Innovator High Tech Electronics Industry Solution, Micropower established a systematic tracking mechanism for the latest document revisions, simultaneously simplifying the data search and retrieval process.

North Sea Electronics AS (NSE) focuses on the advancement of high-temperature electronics tailored for challenging contexts, including downhole applications within the oil and gas sector. Given the demanding scenarios their products encounter, the implementation of a robust product revision management system is paramount for NSE. Through the utilization of the Aras Innovator High Tech Electronics Industry Solution, NSE has not only achieved a notable reduction in product design error costs but also a commendable boost in product profitability. This achievement stems from their more streamlined and efficient approach to product development. The enhanced visibility into processes and the accelerated pace of implementing product modifications empower NSE to respond swiftly to the dynamic shifts in both the market and customer demands.

Imperial Brands faced considerable hurdles with a fragmented product lifecycle system landscape. Siloed teams and disconnected tools hindered collaboration and efficiency across processes. Coping with vast data volumes and global regulations called for a comprehensive PLM overhaul. In this video, David Everson, Senior Manager PLM Process and Systems, Imperial Brands talks about how embracing the Aras PLM platform provided a feature-rich solution to tackle Imperial Brand's collaboration issues and fragmented systems.

Imperial Brands collaborated with Tata Consultancy Services to implement Aras Innovator as a comprehensive Product Lifecycle Management (PLM) solution, enabling them to overcome systems and collaboration challenges and embark on a global-scale business transformation. During the ACE 2023 conference, David Everson, senior manager PLM process and systems at Imperial Brands, shares the remarkable journey of their digital transformation in his keynote presentation.

Imperial Brands previously grappled with significant challenges due to a highly fragmented product lifecycle system landscape. Different teams and departments operated in silos, using disconnected tools and systems, hindering collaboration and efficiency in end-to-end processes. The need to manage vast data volumes and comply with diverse global regulations demanded a comprehensive PLM overhaul. Embracing the Aras PLM platform offered a feature-rich solution to address their collaboration issues and fragmented systems.

Mycronic, a prominent Swedish company, stands as a world leader, providing cutting-edge solutions for the high-tech industry, catering to assembly, display, and packaging needs. Their exceptional solutions find application in diverse fields, from flat screen TVs and displays to life-changing medical implants and even interplanetary space technology equipment.

Faced with the challenge of software end-of-life for their ENOVIA SmarTeam PLM solution, as well as the steep costs associated with other traditional PLM vendors, Mycronic made a strategic decision to adopt the Aras Innovator platform. The choice was driven by the platform's impressive array of functionalities and unparalleled flexibility, offering the ideal solution to meet their evolving needs.

L3 TRL Technology, a UK-based company and part of the leading US defense supplier L3 Technologies, specializes in electronic warfare and cyber security. Despite its agility, the company faced challenges in managing product development due to its smaller company ethos. This led to complexities in handling various product data and searching for the latest versions, causing inefficiencies and wasted time.

Fortunately, with the introduction of the Aras Innovator High Tech Electronics Industry Solution, L3 TRL witnessed a remarkable transformation. Internal collaboration and manufacturing release processes improved significantly, paving the way for scalable and efficient business operations.

Headquartered in South Africa, Delta V Aerospace stands as a youthful, vibrant, and independent aerospace design and development company. Renowned for their progressive and elegant solutions, the company prides itself on optimized business procedures and meticulous testing, ensuring proficiency in their endeavors. As they experienced remarkable organizational growth, they realized that their current data handling structure fell short of supporting their relentless pursuit of excellence. In order to meet and exceed all set requirements, they sought a solution that went beyond ordinary data management systems. Their quest led them to discover the transformative benefits of Aras Innovator, a powerful Product Lifecycle Management (PLM) tool that seamlessly caters to their evolving needs and propels their business to new heights of success.

MIT Lincoln Labs has been working on a project to enable an enterprise digital transformation of how they do their work. They have implemented a solution called Assembly Integration and Test (AI&T) built on the Aras platform. This solution digitally automates a manual process that was previously time consuming and error prone. The new solution was developed in collaboration with Eontes, an Aras Systems Integrator with experience in providing ground-breaking solution to Aras customers. This webinar will explain their solution and provide a clear example of how you can gain this kind of advantage by using Aras as your PLM platform.

SM Power, a power supplies and battery chargers solutions provider catering to diverse industries, faced a rise in product documentation complexity due to their recent growth. Recognizing the necessity for an automated workflow for CAD files and other product design documentation, they opted for Aras Innovator to address this requirement. Drawing inspiration from the successful implementation of the Aras PLM system by their parent company, the Swedish Micropower Group, SM Power embarked on a similar path a few years later.

Consilium specializes in niche markets that require high-security requirements within the global transport sector — onshore and offshore, high-tech, and oil and gas. In one of the industries that Consilium operates, the high-tech industry, Consilium must meet the highest safety standards and product documentation requirements. Consilium chose the Aras Innovator High Tech Industry Solution to track each product and its lifetime certifications.

Learn how a leading technology provider was able to significantly reduce its product development cycle times by leveraging the Aras PLM platform.

Amulet Hotkey, a global provider of innovative computing and visualization solutions, faced numerous challenges in managing its product development process. With multiple teams working on different product components, tracking changes and ensuring consistency became increasingly difficult. In addition, the process of managing product data and associated documents was time-consuming, leading to long development cycle times.

In this webinar, Martin Bladon, Aras Customer Success Manager, will explore how Nick Redfern, NPI engineer, and his team at Amulet Hotkey overcame these challenges by adopting the Aras PLM platform. They will share their experiences implementing and using the Aras PLM platform and discuss how it has improved their ability to manage product data and accelerate product development. If you are a product manager or engineering leader looking to streamline your product development process, this webinar is a must.

Oxford Instruments, the first commercially successful spin-out from Oxford University, has contributed several technological breakthrough products during its 60 years, including the world's first superconducting magnet and fully functioning MRI system. Over the years, the company's growth has led to significant challenges in managing its product development and supply chain processes. Learn how Aras Innovator helped Oxford Instruments to provide a centralized repository for all product data, including engineering designs, specifications, and manufacturing instructions.

Cloud-based software-as-a-service (SaaS) is the clear path forward for enterprise software, and the cloud transition in PLM is underway. According to a recent survey, about ¾ of companies now favor, prefer, or mandate the cloud for new software selections.

Using data collected from their industry research and multiple surveys, Jim Brown of Tech-Clarity discusses why companies should take a "solution first" rather than a "cloud first" approach for their cloud migration strategy.

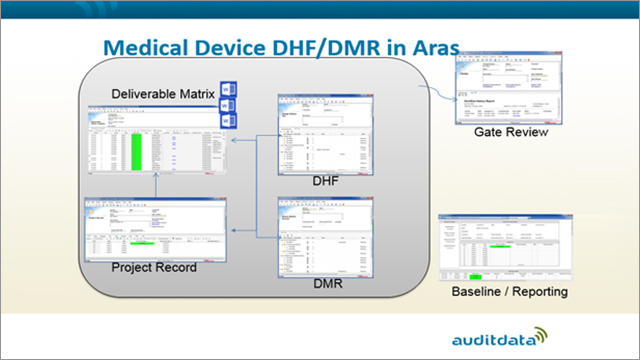

Auditdata handled their documentation by manually signing and scanning paper-based documentation to store them on file servers. This inefficient and complex process resulted in errors and wasted time. By implementing Aras Innovator and the industry-specific medical device PLM solution, Auditdata increased visibility and understanding of data relationships within their environment.

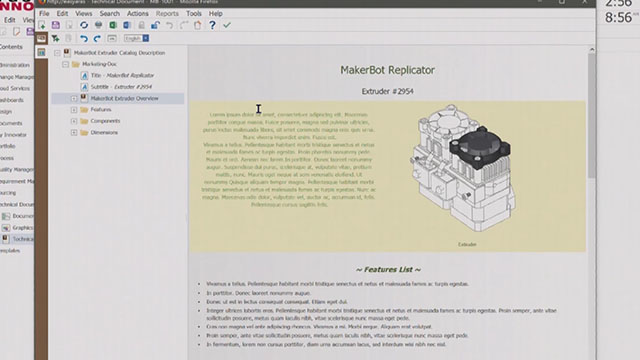

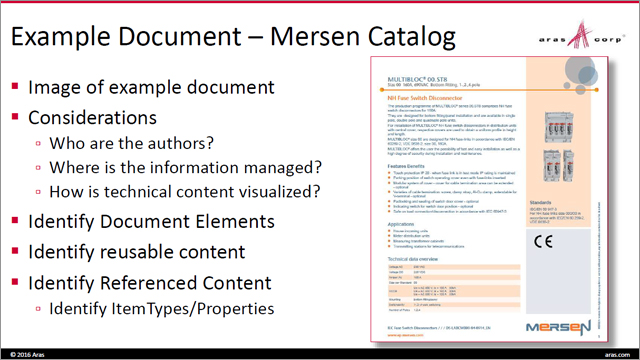

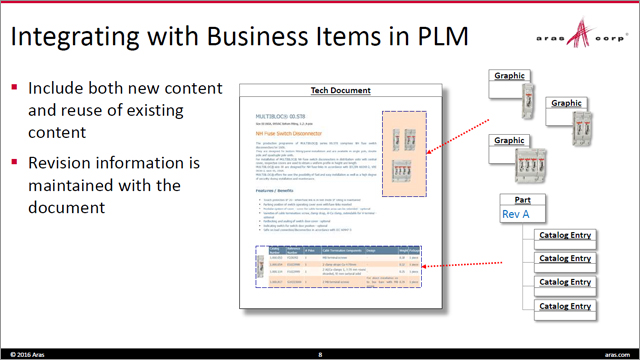

Creating product documentation, like installation sheets and manuals, and keeping them up to date can be challenging and demanding. Many technical publishing systems require the data to be pulled manually from different sources, which is a considerable risk for errors and obsolescence. Aras Technical Documentation is a content authoring that turns your data stored in PLM directly into connected technical publication information – on the same platform and in a modular fashion.

The Technical Documentation Application was introduced in 2015 and is based on the Tech Pub Framework, which is the foundation for our Requirements Engineering and Manufacturing Process Planning Applications. Both the framework and the application have improved for even better usability. This webinar will show the current cycle of enhancements and upcoming features of the Technical Documentation Application.

Kyocera Unimerco specializes in the development of high-quality precision cutting tools for metalworking, woodworking, and composite materials. It is vital for the company to have complete visibility and traceability in their product data. Version control is a significant and complex task for a company like Kyocera Unimerco. As the old system no longer supported this process, the need for a modern PLM platform drove the team to look for a new solution. Today, Aras Innovator is used across the company's tooling division.

If you’ve been reading the news these days, it’s been impossible to miss the buzz around Artificial Intelligence (AI) and how its impact will affect every aspect of our lives, including PLM! AI has the potential for transforming data into information, improving contextual searches, assisting in decision making, spotting data patterns, and providing design insights. This webinar focuses on the benefits and the pitfalls of AI, and how to effectively strike the right balance between AI and PLM.

The current energy crisis has pushed us to rethink our business strategies. Due to the increased energy costs in 2022, manufacturers across industries immediately achieved up to 20% savings by lowering heating in offices and manufacturing sites and improving energy efficiency in buildings and infrastructure.

The speedy transformation shows that there is a huge potential to do more. By consolidating energy-saving activities into a structured approach, manufacturers have the potential to make their businesses much more profitable.

The following questions will be of central interest within the industry:

What part of the product consumes the most energy during production?

How can I improve the overall energy footprint within the manufacturing or supply chain?

Which investment makes an ROI in energy savings and lower overall cost?

Knowing that there are many more challenges to solve on energy costs and consumption, transparency and a structured approach are essential.

In this webinar, you will receive insights on how your business saves costs on parts and manufacturing by consuming less energy and delivering cleaner and more sustainable products for customers. You can provide better products and solutions with access to one data hub that maintains all relevant energy KPIs within your environment.

Not all products are created equal. Axendia's research shows medical device companies still rely heavily on manual processes and siloed systems to manage the medical device product lifecycle. The result is an inability to effectively close the loop from ideation through commercialization and service or obsolescence.

Axendia recently interviewed industry leaders to learn how they harness the power of PLM. Learn how PLM helps medical device companies make informed decisions about when to invest in new product development, when to retire existing products, and how to align with evolving customer requirements. This can lead to a more successful and sustainable product strategy.

Leave the conversation with best practices on transforming your product lifecycle management approach. The result? Accelerated time to market, improved product quality, and seamless global regulatory compliance.

In this Voice of the Customer report developed by Axendia, we explore the key benefits of implementing a Product Lifecycle Management (PLM) solution and how medical device companies are overcoming complex challenges in the life sciences industry. In this report, we will cover:

- Business objectives and goals

- Leveraging digital threads to support product lifecycle intelligence

- The value of PLM from business, regulatory, and technology perspectives

- Overcoming the barriers to PLM implementations

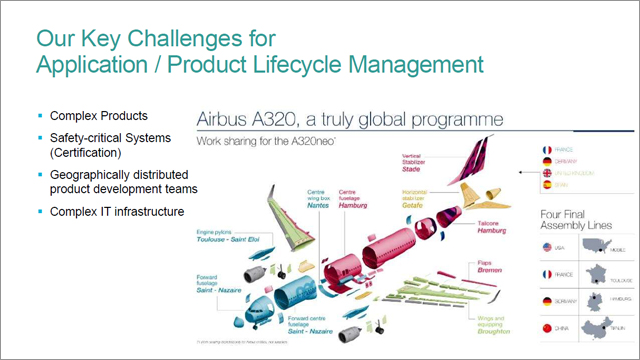

Listen to James Roche from CIMdata, David Ewing from SAIC, and Paweł Z. Chądzyński from Aras share their insights on how digital thread solutions can streamline the product lifecycle, enhance collaboration and communication, and improve regulatory compliance. This discussion includes a review of CIMdata research which indicates that digital thread investment within the ecosystem of industrial users will proliferate in the Aerospace and Defense industry.

Today's products are so complex that companies collaborate more and more with partners during the design and manufacturing phases. Most companies rely on unsecured ad-hoc tools and methods for collaboration, including FTP, file sharing, and email.

During this webinar, you will learn how you can collaborate efficiently in a secure manner while protecting your IP, using the Aras Innovator platform. We will demonstrate how users can define the scope of data to be shared with suppliers based on a 3D mockup from the company PLM solution (or collaboration portal). You will learn how external users can access data from a supplier portal with full PLM capabilities hosted on a DMZ.

Discover how the Aras Innovator platform helps to make your supplier collaboration a success.

"Engineering to Possible" is a Systems Thinking context that holds significant importance for manufacturers. It includes taking proactive measures to manage and mitigate potential disruptions in the supply chain that could impact critical sub-subsystems, manufacturing processes, and distribution. Failing to address these potential disruptions forces organizations into a reactive mode, often lacking insight into the core functionality of key products. This reactive approach leads to unpredictable costs, potential quality issues, and inadequate compliance with regulatory standards.

ANCA, a global tier-1 supplier of industrial cutting devices, had been experiencing challenges in optimizing the integration between their ERP system, data management systems, and internal collaboration processes. They realized there was a problem when ANCA tried to deploy one of their most ambitious new products. Driven by the determination to solve the problem, ANCA looked for a PLM solution with additional integration capabilities that would work well with their ERP systems. They implemented Aras Innovator and Increased team communication and collaboration due to solid integration between their ERP and PLM systems.

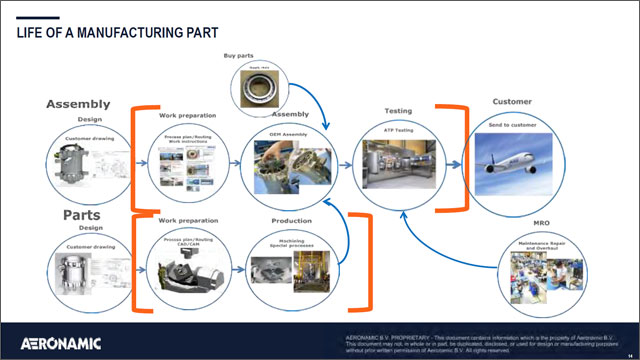

In its pursuit of becoming a top-tier supplier of components to the aerospace industry, Aeronamic needed to improve data visibility and handle regulation and certification procedures more efficiently. Read how Aeronamic centralized its data-handling structure and lowered time expenditure and production costs.

Aras Variant Management application helps manage your product platforms and variants on a single, connected Aras PLM platform. Using functionally rich, intuitive user interfaces, teams in your organization can define and validate product variability rules and apply them to various product structures. Product platforms are managed using breakdown structures with the applicable variability. The application generates valid product variants based on a common underlying platform structure.

A PLM system doesn't guarantee you are ready for any challenges affecting your company or your products. Since no one knows what the future will bring, it is impossible to build a PLM system, or any system for that matter, that will solve any future requirement that may come. You need a flexible, scalable platform that can quickly design, build, prototype, and launch new applications and features.

One example for the medical device industry was the introduction requirements for Unique Device Identification. When this requirement was introduced, no systems were ready for it, and no systems were designed to manage this requirement, which led to a lot of manual work, inefficiency, and loss of traceability.

Because of the flexibility of the Aras Innovator platform, we could quickly respond to this. Within two weeks, we had a fully functional solution that could help our customers manage this new requirement without investing in a new tool, adding mountains of manual work, and adding to the system landscape's complexity.

The Complete Guide to PLM Software Selection: Everything you need to know to make the right decision

Selecting the right PLM software for your organization can be complex and time-consuming. With so many available options, it can be challenging to determine which software solution will best meet your specific business needs.

In addition, many PLM software selection processes have become superficial. These processes often resemble staged performances, where software vendors and implementation partners compete against each other to win your business.

The Complete Guide to PLM Software Selection is designed to help you avoid these pitfalls and make a well-informed decision about which PLM software solution is right for you.

This guide provides a comprehensive overview of the key factors when selecting a PLM software solution. It also guides how to build a business case for PLM adoption, select a vendor, and implement the software effectively.

Download your copy of The Complete Guide to PLM Software Selection today and get the information you need to make a smart decision about your PLM software future.

This eBook summarizes the recent CIMdata research on behalf of the Aerospace and Defense PLM Action Group member companies in collaboration with Aras. The findings indicate that digital thread investment within the ecosystem of industrial users, their customers, suppliers, and solution providers have reached an inflection point. Initial implementations of targeted digital thread solutions have provided value proof points and essential learnings. Now expanded investment rounds are ramping up, guided by these early achievements and with expectations driven by the value potential revealed.

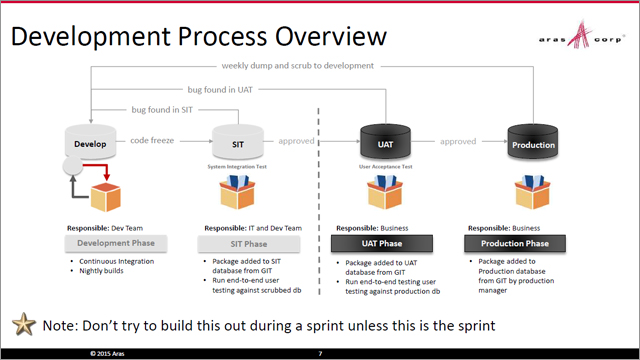

Implementing and operating PLM solutions can be complex due to their many capabilities, interdependencies, and integrations and how they interact with product information and business processes. Read this commentary and discover why CIMdata calls the Aras approach to DevOps “a great choice for companies looking to modernize their approach to Aras Innovator solution configuration management.”

Consumers choose products with ever-increasing features in today's highly competitive commercial landscape. To succeed in this landscape, companies are investing in efficient product development strategies as a key differentiator in determining their success. Adopting a modular product development approach where many product variants are derived from a common platform has become a best practice. However, this approach requires the ability to match the innumerable customer requirements and all the combinations of product options conceived in the development phase. Most of the Variant Management tools available in the market cannot handle this challenge, addressing variability only on the already developed product as it is presented to consumers.

The new Variant Management application in the Aras Innovator platform is designed to cover not only the customer-facing product variants but also the development process of these variants, including the mapping to product requirements and other product representations. It leverages the power of Aras Innovator, including its flexibility and connectivity, to provide a solution that applies to the complete Digital Thread. This allows companies to manage product variants from the start of their development process, addressing complexity in an efficient manner, and reducing the overall product development cycle, thus delivering value to their customers faster.

In this webinar, Rodrigo Britto Maria, Aras presales engineer for EMEA, will demonstrate how the Aras Variant Management application can be used in a product development scenario, highlighting the connection with product requirements and discussing the key differentiators that can help you manage the variability of your products across their development lifecycles.

Managing and coordinating product development across multiple locations while consciously acquiring new companies comes with business challenges. If your organization is in a similar situation, this webinar is a must.

In this webinar, Kendrion, who manufactures high-quality electromagnetic systems and components for industrial and automotive applications, will share how they went from disparate software systems to a centralized, digital backbone with Aras Innovator. They now maintain a single source of truth for their data coming from more than 20 sites worldwide.

Find out why they selected the cloud-based Aras Enterprise SaaS (software as a service) platform for their dynamic scaling and easy integration with other systems. And why they went with a SaaS solution rather than on-premise? We will review how they resolved other business challenges as a multi-side and constantly growing organization with a SaaS product lifecycle management system (PLM).

Software is playing an increasingly important role in the development of future products. While mechanical, electrical, and electronic elements are often interconnected, software/ firmware is only sometimes effectively integrated into traditional product data management systems.

In recent webinars, we have demonstrated the benefits of adopting a model-based systems engineering and product lifecycle management approach, which allows for the automatic maintenance of a bill of materials and streamlined change processes across disciplines.

In this webinar, we will show how software/firmware can also be managed in an integrated approach using ALM/PLM best-in-class integration. This will provide a comprehensive view of the integrated development process and ensure that all disciplines work together seamlessly.

Recently, the market handed us amazing examples of what happens when companies fail to keep up with the technologies that are strategic to their competitiveness. Delaying technology upgrades has had an enormous impact on Southwest’s business. Legacy technology systems could also have contributed to Ford’s Mustang Mach-E production errors, where CEO Jim Farley disclosed they have “a mile of wires it didn’t need.”

Both companies are struggling to meet the demands of today's market due to their use of outdated legacy systems. How can modern enterprise systems help companies overcome these challenges and prepare for the future?

Join us for an exclusive webinar where Aras experts will provide commentary and dive deep into the consequences of using outdated systems, explore the risks and benefits of modernizing technology, and how companies can break free from their legacy systems to become more agile, efficient, and competitive.

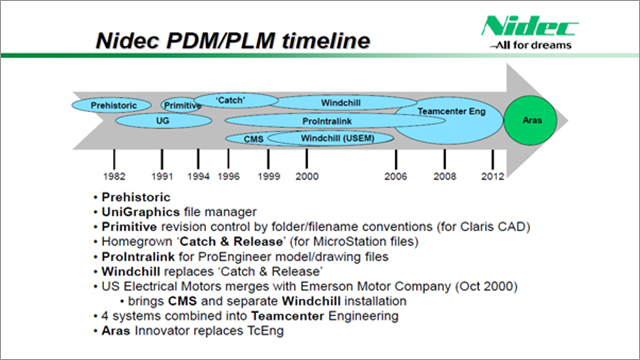

Nidec Corporation, a leading global comprehensive motor manufacturer, chose Aras Innovator to centralize data from various sources due to their acquisition of multiple companies. Hear how they successfully centralized their data using Aras from Kamran Aftab, PLM management leader at Nidec.

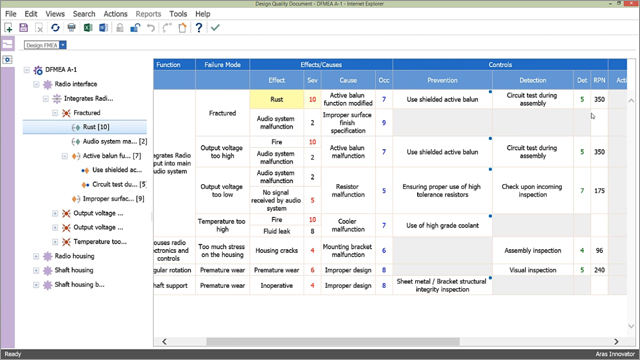

Medical device manufacturers must reduce the risk of potential hazards and harm when users operate their devices. Device failures from intended and unintended use must be identified, understood, and controlled. Managing risks in siloed document-driven processes makes it difficult for medical device manufacturers to connect all risk-related data and understand the impact of product changes coming from design and R&D. Manufacturers need a system that brings quality, risk, and product data together in one place.

"If you digitize a bad process, you will get a bad digital process."

With 20+ years of PLM implementation experience, we have learned a few lessons on what makes or breaks a PLM project. First, if you do not know your digitization strategy, you will get lost at some point trying to reach an unknown goal. And secondly, if the entire organization and external partners is not involved in the PLM implementation, there is a high probability that it will fail. No matter how much money you spend.

In this webinar, we will show you concrete examples of what to consider, and how to prepare and set up a PLM project that is not doomed to fail, making sure that you reap maximum benefit from your PLM solution.

In the past, Amulet Hotkey faced challenges due to inconsistent management of product data across spreadsheets and multiple disconnected systems. This issue harmed their data quality and productivity. However, by adopting Aras Innovator in the cloud as their primary system with strict data security control, Amulet Hotkey has experienced a drastic improvement in their efficiency, reducing the time it takes to assemble and send data packages to third-party manufacturers from 3-4 weeks to just 3 minutes.

MacGregor, a world-renowned provider of cargo and load handling solutions for the global maritime industry has developed an award-winning monitoring solution with Aras Innovator as its supporting IT platform.

If you are from a product company, an EPC or an Owner/Operator engaged in capital projects, and interested in how others manage information from early phase design through to operations and maintenance by introducing structured and connected data, then this webinar is for you.

Bjorn Fidjeland from plmPartner offers examples of what kind of information structures are important to focus on and manage throughout the lifecycle of any plant or facility as well as how they relate to each other. Listen to how different companies have obtained traceability and control from early plant design to product selection or even in-house product design and manufacturing, through to installation, commissioning and ultimately operations, maintenance, and de-commissioning.

Learn how companies are utilizing structured and linked data as a foundation for their digital twins, and why this linked data is such an important enabler to harvest the benefits promised by digital transformation.

Sébastien Grau, explique pourquoi son entreprise a choisi de devenir un partenaire d'Aras Innovator dans le domaine du conseil et de l'intégration.

David Breneur, chef de projet PLM chez Haulotte, explique comment la plateforme PLM Aras Innovator permet de créer une véritable continuité numérique, garantissant la traçabilité et la collaboration au sein de toute l'entreprise.

Everything in design starts - and ends - with requirements. They are a critical part of a digital thread and provide the context of what the product does. Add the ever-exploding product complexities and the challenges keep growing. Separate, stand-alone tools for managing requirements make traceability of requirements difficult. This is why managing requirements in a PLM platform is critical to improving interdisciplinary collaboration and verification. Hear the benefits of integrating requirements management across the entire product lifecycle with the digital thread.

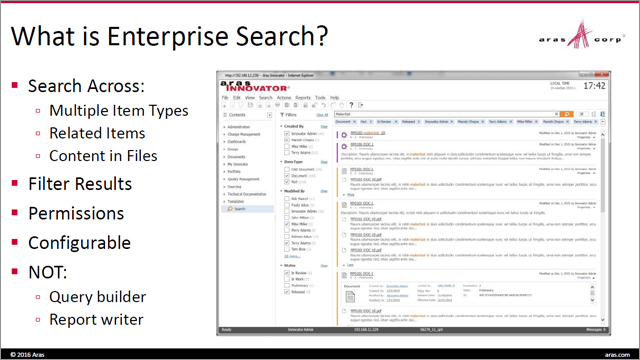

Most companies today struggle to manage all of the data that is generated during product development. Much of this data is contained in silos around the enterprise with little access for the business. One solution to this challenge is the ability to create interactive dashboards that display PLM data. Learn more about this illuminating ability from Aras that will be rolling out in phases this year.

Toyota Motor Europe relied on the manual exchange of complex spreadsheets to share data, an unsustainable process due to the number of architectural variants and related simulations. These spreadsheets were devoid of any connection to the rest of the product data and were not managed under configuration control. The pedigree, maturity, and connectivity of the data were often unclear. Management of the engineering division recognized that the existing process was not sustainable without a new data management platform. The original spreadsheets are now replaced by the “single source of truth,” the digital thread in the Aras platform that covers the engineering data for vehicle dynamics performance. The variant-design-simulation relationships are managed within this system-centric digital thread regardless of where the system and design details are authored.

Excel-based management makes finding the most current data very difficult, with users making copies, changing data, or saving new versions of documents. When Tamturbo went through a period of rapid growth, which resulted in more complex products and data to manage, they quickly realized the importance of systematic data management.

Tamturbo produces oil-free, touch-free, and care-free turbocompressors for several industries and provides 24/7 remote monitoring of their equipment. It is critical for all departments – from sales and service to designers and developers – to have easy access to accurate product data.

In this webinar, Tamturbo’s Ollipekka Jaatinen and Fulvisol’s Petri Surakka will discuss how Tamturbo achieved a clear, traceable view of the entire lifecycle of its compressors by federating all data into one system available across their entire value chain.

Please register today and get insights on how a growing organization can leverage product lifecycle management (PLM) to boost its productivity, save costs on outsourcing resources, and deliver design structures for customers. With access to one data hub, users can connect their CAD system to Aras Innovator, ensuring the accuracy and completeness of all CAD libraries and much more.

Les coûts énergétiques constituent le plus grand défi auquel l'industrie est confrontée. Néanmoins, de nombreuses entreprises se sont contentées de mesures d'économie d'énergie faciles à mettre en place. Une approche structurée fait plutôt figure d'exception.

Le nouveau livre blanc d'Aras ‘Améliorer les Economies d'Energie dans l'Industrie’ révèle comment les industriels peuvent utiliser la numérisation pour réduire de moitié leur consommation d'énergie. En recourant à un audit énergétique systématique et à une analyse précise des données collectées, les entreprises peuvent acquérir une connaissance détaillée de leur chaîne de valeur afin de valoriser les possibilités d'optimisation.

Circor Deltavalve is the global standard for safe and reliable refinery valves. Their innovative solutions have created levels of safety and reliability previously unattainable. Listen to this 2-min video on how Circor Deltavalve broke free from the constraints of their legacy PLM system to meet their business goals by leveraging the open, flexible, easy-to-use Aras Innovator platform.

Our Aras Product Development team has been releasing application, connector, and platform updates at an incredible pace! With our robust release cadence, you may have missed some great new features that were designed with you in mind!

Hear from John Sperling, SVP Product Management, for a 30-minute overview and demonstration of all the new capabilities to help you continuously improve on your Digital Transformation journey.

Rising energy costs, a high inflation rate, and an acute shortage of skilled workers are putting tremendous pressure on European industrial companies. Winners and losers are made in times of crisis and individual companies can control how well they are positioned during times of uncertainty.

To assess how prepared Europe’s industry is, Aras surveyed over 400 decision-makers from 19 European countries; nine out of ten survey participants are convinced that sustainability and economic success are no longer a contradiction in terms. For them, getting ahead with ESG (Environmental, Social, Governance) is a critical factor for building the resilient businesses of the future.

During this webinar Frederic Weiller and Matthias Fohrer will share with you how your company can both comply with legal requirements and capture the economic potential of sustainable business practices.

Hanwha Phasor is a British company with a mission to design broadband antennas capable of delivering mobile internet access via satellites anywhere in the world. Today, the London-based company is preparing its first product, the M6 phased array antenna, planned for launch in 2025. A focus that has added an extra layer of complexity to how departments collaborate with product data throughout the organization.

To transform design data into state-of-the-art low-profile antennas. Hanwha Phasor needed a PLM system to transfer released and approved design data to manufacturing to support efficient collaboration of design data between engineering and manufacturing.

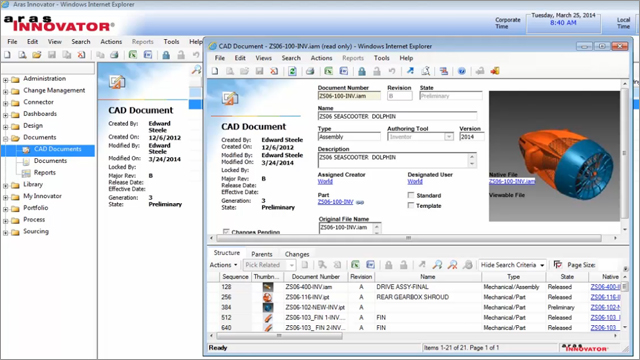

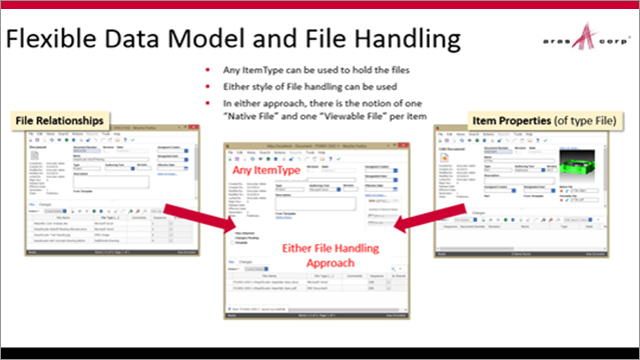

When access to CAD data is limited to CAD designers, the only users who can realize the value of visualization, collaboration, and coordinated change based on highly intuitive, graphical representations of the product are the users who created those representations in the first place. In this white paper, we look at the current CAD and PDM landscapes and outline the impact of an unconnected CAD environment. Then we examine the benefits of integrating CAD data into a PLM system and the importance of a digital thread that connects that data with departments, the extended enterprise, and the supply chain.

Accelerate your new product introduction with the innovation twins ALM and PLM. Products are getting smarter each year, increasing the number of lines of code and dependencies between hardware components, sub-systems, and the system in its entirety. People from different disciplines must work together to make products and systems work reliably. The different engineering disciplines involved typically work within their specialized tools: software engineering in their Application Lifecycle Management (ALM) system, electrical engineering in data management tools, and mechanical engineers manage data in their PLM system. The know-how exchange between those silos is often poor and results in substantial manual overhead.

In October 2022, we showed the technology enabling the data exchange between ALM and PLM. This time, together with PROSTEP and their OpenPDM Integration Platform, we will explain the business case for the collaboration between ALM and PLM. We’ll answer the question “why should you care” about the marriage between ALM and PLM.

Vard Electro is a world-class supplier of complete electrical systems for ships, including Control, Power, and Communications systems. The company recently changed its approach to become more product-oriented, and Aras Innovator plays an important part in making engineers and designers work much more efficiently.

In 2022, businesses responded to enormous challenges and ongoing change. This won’t slow down in 2023, but now the name of the game is surviving economic downturns, elevated energy costs, and supply chain disruptions, all while making the right investments in products. And while keeping in mind that many of the world’s greatest companies started during economic downturns, which often present the best opportunities for growing a business while others are retreating.

In this webinar, Rob McAveney, Chief Technology Officer and Jason Kasper, Director of Product Marketing, Aras, explore trends and opportunities to invest in supporting your business challenges today while creating the flexibility to adapt to future business conditions and meet the challenges of tomorrow.

Nissan Motor Co., Ltd. adopted Aras Innovator as the development platform for its electronic control systems. Nissan's success in streamlining configuration management was made easy by Aras Innovator's 'easy to build,' 'easy to align,' and 'easy to connect' characteristics.

Aras Innovator contributed to efficiently managing complex in-vehicle software variants between Nissan Motor and its alliance partners. With Aras, Nissan has realized the benefits of integrating with its alliance partners, and constructing a digital thread is becoming a reality.

Hausse des coûts de l'énergie, taux d'inflation élevé, pénurie criante de travailleurs qualifiés, tout cela est devenu un état de fait permanent pour les entreprises en Europe. Il n'y a aucun moyen de savoir combien de temps cela va durer, mais les organisations peuvent contrôler leur stratégie en période d'incertitude.

Afin de mesurer l'efficacité de l'industrie européenne à cet égard, Aras a interrogé plus de 400 managers de 19 pays européens.

Les responsables de secteurs tels que l'automobile, la construction mécanique, l'aviation, la chimie ou la technologie médicale souhaitent-ils faire différemment ou mieux à l'avenir ? Vous trouverez les réponses à ces questions et davantage dans l'enquête d'Aras, "L'industrie européenne en transition".

JTEKT Thermo Systems Corporation has improved the efficiency of their make-to-order manufacturing operations using Aras Innovator. The company was required to build an optimum database for each piece of equipment in their individual make-to-order manufacturing process and focused on Aras Innovator to enable flexible system construction.

Europe is currently experiencing a dramatic two-fold energy crisis. In addition to the risk of an energy supply shortage, European organizations also face rising energy prices. This situation is driving companies of all sizes to reduce output and be ready to shut down their production if necessary. Energy-intensive businesses must decide between weathering the storm in Europe or relocating production to regions with lower energy prices. These scenarios will dramatically affect each company's competitiveness, sustainability, and activities.

In this webinar, Frederic Weiller, director of Field Marketing for Aras Europe, and Patrick Willemsen, director of Aras Technical Solutions EMEA, will share how the energy-conscious solutions available today can help you manage your carbon footprint and comply with environmental regulations, helping decision-makers achieve their sustainability goals.

Companies are experiencing increased risk of IP theft, overworked IT staff, adjusting to more global remote employees, and quickly changing business processes. Having the right tools, processes, and expertise in place is essential, not just to protect your company, but to grow.

Hear from Aras experts as they discuss how Aras Enterprise SaaS helps de-risk your PLM environment.

Retour sur l’événement Aras Innovator Live Paris 2022.

Une journée entière dédiée aux clients et prospects, aux partenaires, aux influenceurs et aux intégrateurs avec des présentations sur les différentes fonctionnalités offertes par la plateforme Aras Innovator.

Téléchargez les présentations.

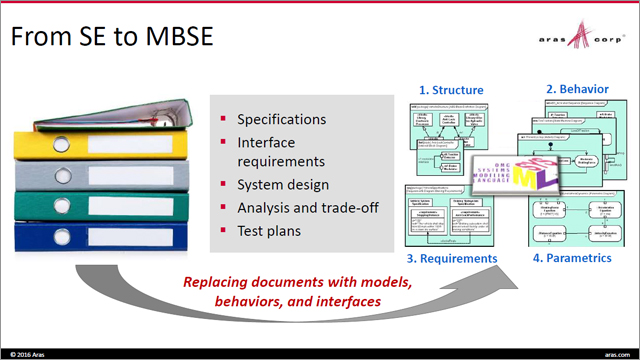

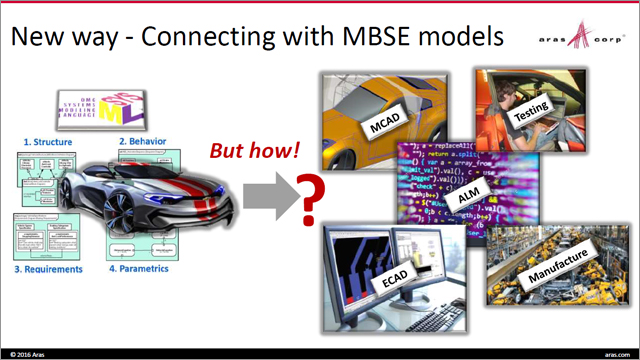

We are transforming from focusing on products to increasingly interdisciplinary and networked systems. These systems are built using a combination of mechanical design, E/E development, and software engineering. The increasing interdependencies between engineering artifacts require new methods to manage engineering change. Against this background, the potential of integrating Model-Based Systems Engineering (MBSE) and Product Lifecycle Management will be highlighted in this webinar.

The heterogeneous data from various development tools require new approaches to engineering change management. With the help of MBSE models, the impact of a change can be analyzed across development disciplines. At the same time, a PLM backbone can manage formal changes via workflows that cross IT system boundaries. The interaction of the systems and a connection via EAN-CAD/Software-Integrated Development Environment (SW-IDE) will be highlighted in the webinar.

Aras Product Manager Leigh Young, Rik Rasor of Fraunhofer Institute for Mechatronic Systems Design (IEM) and Robert Huxel, director of Business Development & Marketing, XPLM, show the benefits of interdisciplinary change management. They will share best practices based on Fraunhofer IEM’s 10 years of experience.

Aras Variant Management allows you to define and manage complex configurations of product variants across engineering disciplines and organizational boundaries. This enables you to efficiently define and manage variability in product platforms, maximize module reuse, reduce cost of quality (COQ), lower costs, and shorten time to market. Establishing a consistent approach to authoring and managing variability is an essential element of your product strategy.

Today, spreadsheets still play a significant part in everyday work life in engineering and manufacturing organizations across the globe. But as the demand for instant access to product data is increasing, so is the need for interconnected product data management tools and integration between enterprise systems. Enter Aras PLM, a data management platform that connects information from multiple sources and enables on-demand access to all product data.

Most companies that aim to deliver profitable products and solutions are now also challenged to support a sustainable future for our planet. Global regulations will play a significant role. For example, ESG (Environmental, Social, Governance) reporting toward Scope 1, 2 and 3 emissions will help companies, investors and consumers where to put their money.

For products and solutions, the environmental impact is mostly defined during the concept phase, where business and design decisions create the major constraints. New business models, like Products as a Service, combined with Modular/Repairable/Upgradeable products are likely the to-be models for a sustainable future.

To run these new business models competitively and efficiently, a company must implement a data-driven PLM infrastructure. This webinar will show how the Aras’ PLM-infrastructure can help businesses in their journey. Aras Innovator offers the platform, OOTB (Out-Of-The-Box) applications, connectivity, and flexibility to support data-driven processes and the transformation to new business models. We will demonstrate the product data traceability from cradle-to-cradle within and beyond the Aras platform.

55% des décideurs en France estiment que leur entreprise fait aujourd’hui face à des défis plus grands que jamais.

Aras, l’un des principaux fournisseurs mondiaux de solutions PLM pour concevoir, construire et exploiter des produits complexes, dévoile les résultats de son étude inédite sur le thème : « Le PLM au cœur des nouveaux défis industriels ».

Réalisée auprès de 120 décideurs de premier plan en France, cette étude permet de comprendre les grands enjeux auxquels sont aujourd’hui confrontées les entreprises industrielles et quels sont leurs atouts et leurs freins pour s’adapter au changement

Creating a resilient enterprise ecosystem requires a massive amount of change by creating new ways of thinking, connecting, and collaborating — all of which need access to a precious and often misunderstood resource — product data. This data needs to be made available to all who need it, while keeping it secure as it moves throughout the enterprise. Watch this video to learn the obstacles, solutions, and value in creating resilience in your organization.

Check out our webinar, "Move from Digital Trauma to Digital Nirvana" today.

A special case of risk management is in the development and marketing of medical devices. Designing, ensuring, and certifying that they are safe for human interaction be it for daily patient care, invasive or non-invasive, diagnostic procedures, or scientific research. The risks may extend to other patients, operators, external equipment or the environment on a micro or macro scale.

The challenges, however, are that risks can present themselves at any point in the lifecycle of the product. Capturing and assessing all risks is both difficult, time-consuming, and error-prone because many medical device manufacturers today are dependent on traditional paper-based risk management processes.

Increase your risk management effectiveness. Learn more in this whitepaper about how to improve your risk processes with automation and change control.

Product Lifecycle Management is essential for all manufacturers that face the demand of rapid creation of designs and many product variants. The need to instantly access information across multiple stakeholders upstream and downstream of product design, has made the move from PDM to PLM imperative. Aras Innovator provides a natural, easy migration path to PLM from legacy PDM tools. With its flexible, scalable, low-code platform, Aras Innovator easily adapts to your organization's existing processes without the need for costly software customization. In this webinar, you will learn how to power up your PDM to Aras PLM as you take the first step towards Digital Transformation.

Systems Thinking is essential to managing exploding product complexities. Companies are investing in Model-Based Systems Engineering (MBSE) methodologies and tools. Unfortunately, traditional product lifecycle management (PLM) software was built to manage the BOM (Bill of Materials), while MBSE’s focus is on the design intent prior to defining the BOM. This creates a gap in any digital thread. This paper discusses three examples of the successful integration of MBSE with a PLM platform resulting in a complete tool-agnostic digital thread.

The increasing complexities of today’s products can derail market opportunities, increase costs, and challenge resources. Managing that complexity increases the need to coordinate and optimize across multiple systems, disciplines, and domain silos within the OEM and across its distributed network of partners and suppliers.

Systems Thinking is an essential part of digital transformation since both focus on how organizations transform the way people think and use data models, tools, and processes to manage the opportunities and challenges of product complexity.

How do you create an enterprise ecosystem to ensure efficient and effective use of product data? Most organizations think it is simply about connecting siloed data. The reality is a successful digital transformation requires new processes and the flexibility to disrupt standard operating procedures and let go of comfortable, yet outdated tools. Read this executive summary to discover new ways of thinking, collaborating, and connecting with a digital transformation platform.

Accelerate your new product introduction with the innovation twins ALM and PLM. Many products are becoming smarter and more complex, increasing the number of lines of code and dependencies between hardware components, sub-systems, and the system in its entirety. People across different disciplines must work together to make systems work together in a reliable way. The different engineering disciplines involved typically work in specialized tools: software engineers work in Application Lifecycle Management (ALM) systems, electrical engineers in data management tools, and mechanical engineers manage data in their PLM system. Knowledge sharing and data exchange between these systems is often poor and results in substantial manual overhead.

Together with PROSTEP and their OpenPDM Integration Platform, we will show the collaboration between ALM and PLM. The out of-the-box connectors of OpenPDM integrate product data for better, faster, and more efficient product development.

Exploding product complexity often result in overdesigns, functional failures, release delays, or costly leaner expansion of workforce. These are not new, but product complexities are making them that much more impactful. And that is one of the primary drivers beyond digital engineering initiatives: evolve people, data, and processes to effectively manage these complexities. But do you know how reach these goals? What are the key success enablers? The key to understanding that is in understanding the role that Systems Thinking has in mitigating functional product failures.

Are you using your data efficiently? How do you keep the little things from falling through the cracks? Aras Innovator® is a platform that can help you stay on top of your product data. In this video, we examine the daily routine of two CAD engineers. Both use an industry-standard PDM tool to manage their CAD design files and all other files that might be associated with this process. The main difference is that Jane’s company has integrated its CAD environment into Aras Innovator. In contrast, Bob’s company does not have a Product Lifecycle Management (PLM) solution to share its CAD data with the rest of the organization and partners in the supply chain.

Racal Acoustics produces audio devices, in-ear headsets, field telephones, and handsets, all specifically tailored to military, paramilitary, and first-responder markets. Before, the company was hampered by inefficient processes where it could take 4-6 weeks to release a new product. Therefore, it was important for the product development team at Racal Acoustics to eliminate all ineffective procedures that increased the time to market for new products. The implementation of Aras Innovator with the industry-specific Aras for High-Tech Electronics solution quickly led to significant efficiency improvements in managing electronic drawings as well as in producing data packs. Download the case study to read the full story.

Aras Technical Documentation helps companies who design, and document complex products to render controlled product data as content while conforming to a document schema through efficient document authoring processes within and across disciplines Unlike traditional PLM providers, who rely on third party applications external to the document creation process, we help you to accurately reflect current product data as documentation so you can document legally binding obligations with stakeholders while properly documenting multi-domain design and testing of complex products.